Products

New Products

Recycling Automatic Treatment Bio-Tech Food Waste Composter

Recycling Automatic Treatment Bio-Tech Food Waste Composter Commercial Food Waste Composter For Kitchen

Commercial Food Waste Composter For Kitchen Food Waste Digester Organic Kitchen Waste Disposal Composter For Commercials

Food Waste Digester Organic Kitchen Waste Disposal Composter For Commercials Commercial Garbage Disposal Food Organic Waste Composter

Commercial Garbage Disposal Food Organic Waste Composter Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste

Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste Vertical Type Glass To Sand Machine

Vertical Type Glass To Sand Machine- All products

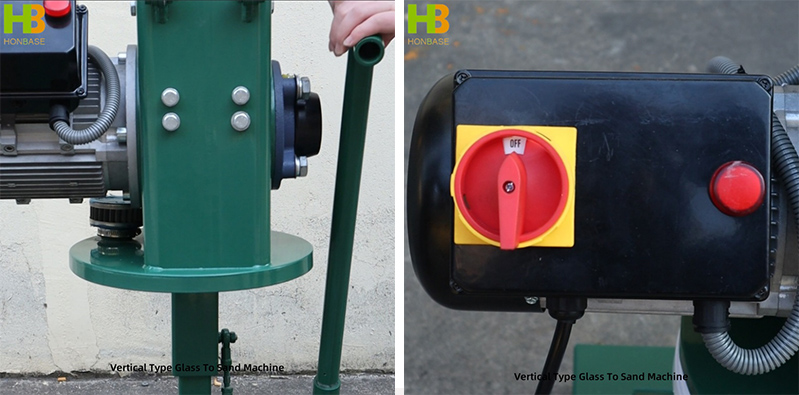

Vertical Type Glass To Sand Machine

The HONBASE Vertical Type Glass to Sand Machine is designed to efficiently crush glass bottles into particles through a combination of cutting, impact, and extrusion. Featuring good stability, low noise, and no vibration, this machine is widely applicable in industries such as pharmaceuticals, food, and chemicals. It offers high efficiency, energy-saving operations, and is equipped with durable wear-resistant parts. The machine can process various types of glass, with adjustable discharge particle size. Its compact design, low maintenance requirements, and uniform particle output make it a valuable tool for various applications, including recycling and the production of fiberglass-reinforced products.

Send Inquiry

Product Description

1. Product Introduction of Vertical Type Glass To Sand Machine

The HONBASE Vertical Type Glass To Sand Machine is a kind of equipment specially used to break glass bottles into particles. Its working principle mainly uses the interaction of moving knife and fixed knife, through cutting, impact, extrusion and other ways, the material broken into the required particles. The equipment has the advantages of good stability, low noise, no vibration and so on. It is widely used in pharmaceutical, food, chemical industry and so on. The HONBASE Vertical Type Glass To Sand Machine pays attention to the design of operation safety and convenience, at the same time has the advantages of high efficiency, energy saving. The wearing parts are made of high hardness, high toughness and multi-alloy wear-resistant material, has long service life, has low energy consumption, has high efficiency and has uniform discharge.

The application of the HONBASE Vertical Type Glass To Sand Machine is not only limited to glass bottles, can also deal with beer bottles, industrial glass cans, automotive glass, glass packaging products, according to different needs, discharge particle size can be adjusted at will, the processed material can be fibrous or powdered. This kind of equipment has a wide market value. The pulverized glass fiber reinforced plastic powder can be used in the manufacture of glass fiber reinforced plastic safety helmet, glass fiber reinforced plastic oxygen cylinder, glass fiber reinforced plastic pipe and other products. In aerospace, railway decoration construction, household furniture, display advertising gifts, building materials sanitary, process yacht docking material, sports sanitation engineering and other industries have a wide range of applications.

Glass bottle mill has broad prospects for development, its easy shape, can be customized, color at will deployment characteristics, makes FRP products in the performance, use, life attributes are much better than traditional products, is favored by businesses and sellers.

2. Product Parameter (Specification) of Vertical Type Glass To Sand Machine

| Product Specifications | |

| Brand Name | Vertical Type Glass To Sand Machine |

| Model Number/Specification | HB-VGTS |

| Automation | Manual |

| Treatment | Pre-treatment |

| Applicable Objects | Glass bottle |

| Feed Type | Manual control |

| Frequency (Hz) | 50Hz |

| Voltage (V) | 220V |

| Rated Power Consumption/Electric Heating Power | 1.5Kw |

| Role | Glass bottle crushing |

| Machine Material |

Carbon steel |

| Grinding Chamber Material |

Carbon steel |

| Width (mm) | 500 |

| Height (mm) | 1330 |

| Deep (mm) | 486 |

| Input Capacity/Production Capacity | 15pcs/min |

| Treatment Time | Real time |

3. Product Feature And Application of Vertical Type Glass To Sand Machine

The HONBASE Vertical Type Glass To Sand Machine features include the advantages of the overall design modelling beautiful, compact structure, less wearing parts, convenient maintenance, broken than large, uniform discharging, granularity and less powder phenomenon, low energy consumption, maintance, discharging granularity is adjustable.

The glass bottle crusher is a small mobile crusher, has the following significant advantages:

1. The overall design is beautiful, compact structure, this design is not only beautiful and generous, and compact equipment is usually more efficient, can better adapt to a variety of work scenes.

2. Less wearing parts, reduces the maintenance cost and replacement frequency of the equipment, also reduces the maintenance workload of the operator.

3. Easy maintenance, means that if the equipment fails in the use process, can be quickly repaired, reduce downtime, to ensure the continuity of production.

4. The crushing ratio is large, can handle a wider range of materials, improves the applicability of the equipment.

5. Uniform discharge, to ensure the consistency of product quality, is conducive to subsequent processing and treatment.

6. Uniform particle size, powder phenomenon is less, reduces the production of fine powder, improves the utilization rate of materials.

7. Low energy consumption, in line with the requirements of energy saving and environmental protection, reduces the production cost.

8. The discharge particle size is adjustable, can adjust the discharge particle size according to different needs, increases the flexibility of the equipment.

Application

Saloon

Restaurant

Inn

Kitchen

Laboratory

4. Product Details of Vertical Type Glass To Sand Machine